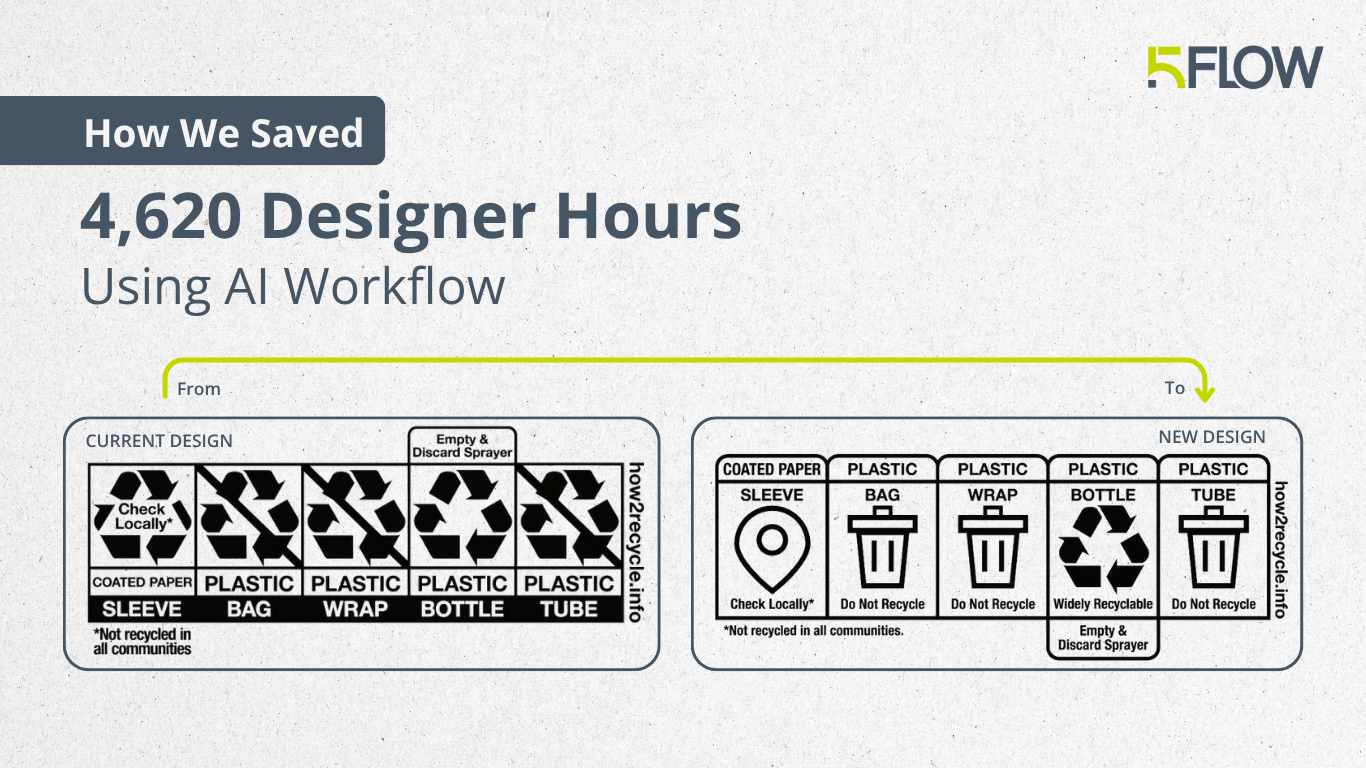

Rebranding 14,000 packaging labels is no small task. That would’ve consumed 4,620 designer hours.

But with smart automation, and AI, 5Flow delivered the project on time, at scale, and without compromising accuracy.

This is a real-world example of AI in action, solving creative production challenges at scale.

Context

In today’s fast-moving consumer goods landscape, brands face growing pressure to communicate clearly and responsibly with consumers, especially around recycling and sustainability.

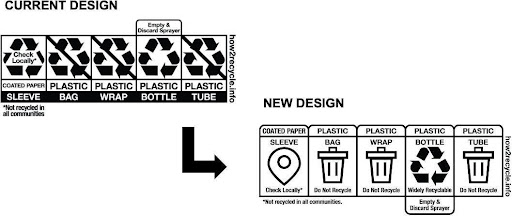

That’s why GreenBlue’s How2Recycle® program recently launched its updated How2Recycle Pro Label, designed to provide clearer, more actionable guidance for consumers.

The challenge:

For How2Recycle, the ambition was clear, but the execution was daunting.

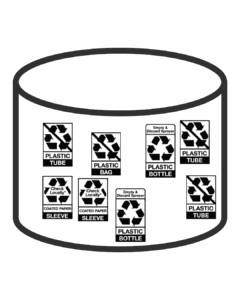

- 14,000 unique label variations needed to be redesigned, validated, and delivered

- Completing this manually would have required thousands of designer hours.

- The launch deadline was at risk without an automated solution. That’s where 5Flow came in.

The solution:

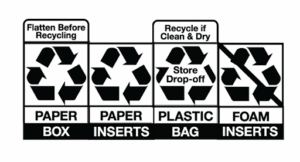

We realized it wasn’t a design problem: it was a data and pattern recognition challenge. Each label contained repeatable elements that could be intelligently recognized and reused. With an automation-first mindset, we built a custom artwork Management solution to solve this project.

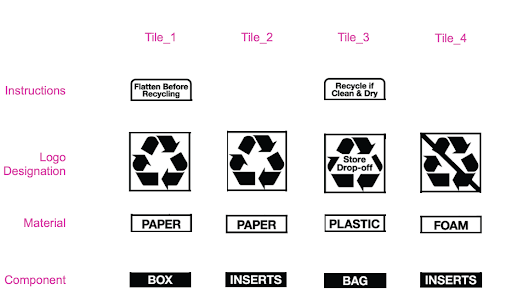

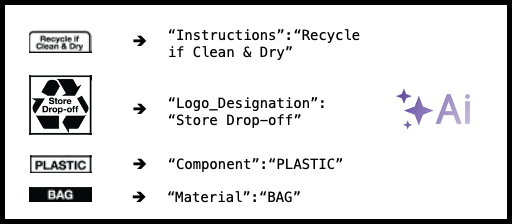

Step 1: Label segmentation: We developed a pixel identification algorithm that broke down each label into four core components: (1) instruction, (2) logo type, (3) material, (4) component.

→

Step 2: Smart matching: Tiles were automatically checked against a central database. Matches were pulled instantly; new ones were read with OCR (optical character recognition) and stored with a unique code via our management solution.

This created a central database that eliminated duplicate work and ensured efficiency.

Step 3: Automatic generation:

Updated PDFs were generated automatically in the new design template, guaranteeing accuracy, consistency, and speed across thousands of assets.

The Results

- 14,000 labels converted on time

- 4,620 designer hours saved

- 81% efficiency gain, translating into cost savings

What This Means for Brands & Creative Teams

This project is proof that AI and automation are ready today to solve real creative and supply chain challenges.

At 5Flow, an artwork management solution provider for brands, we help brands:

- Simplify complexity across packaging and labeling.

- Guarantee consistency and compliance in regulated industries.

- Scale creative operations without adding headcount.

- Co-create custom workflows when out-of-the-box isn’t enough.

5Flow is a perfect artwork management solution for brands and teams looking to push boundaries and turn complex creative flows into automated, scalable systems. Get in touch with 5Flow to streamline packaging, reduce errors, and scale your creative workflow with AI. Contact us today to get a demo.

FAQs

Can 5Flow’s AI workflow be customized for other brands or industries?

Yes. 5Flow specializes in creating custom automation workflows that simplify complex creative operations across industries, from packaging to regulatory design.

What were the measurable results of the project?

5Flow delivered 14,000 redesigned labels on time, achieved an 81% efficiency gain, and saved 4,620 designer hours while maintaining design accuracy.

How does AI improve packaging and labeling workflows?

AI reduces human error, accelerates production, and ensures design compliance by identifying repeatable patterns and automating repetitive design tasks.

What technologies were used in this AI workflow?

The solution used pixel identification algorithms, OCR (Optical Character Recognition), and automated PDF generation to streamline creative production.

How did 5Flow save 4,620 designer hours in this project?

By using AI-driven automation to segment, match, and automatically regenerate 14,000 packaging labels, eliminating repetitive manual work and ensure consistency.